A new ecologically friendly and moisture-resistant building material has been created in Latvia. Scientists at the State Institute of Wood Chemistry have developed it from tree bark, reports Latvian Radio.

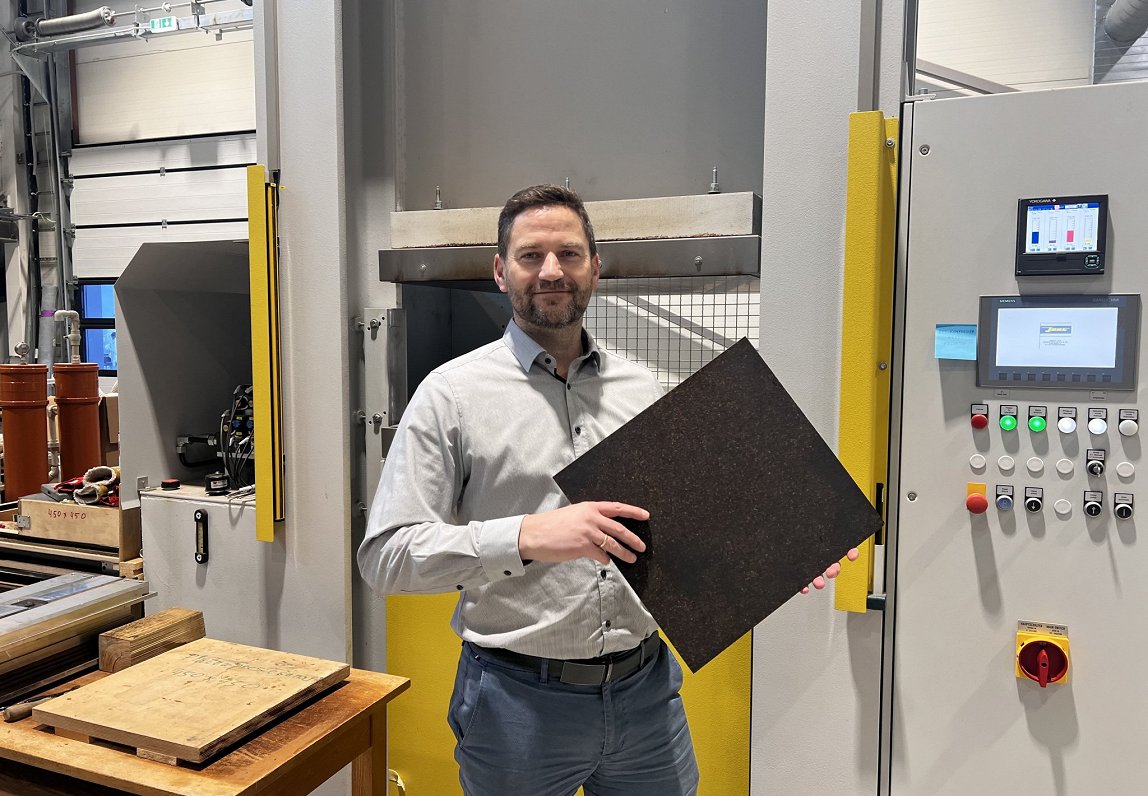

A form about half a meter square and a few millimeters thick. It is heavier than it looks, rather dense, bitter chocolate in color, even a little darker in places, and with a burnt smell. The sample of the new building material was created in the international project “BarkBuild”, one of the participants of which is the Latvian State Institute of Wood Chemistry .

“We have created two types of binders: one is for chipboard, the other is for plywood, an impregnation material, a coating that is water-based; it’s a very popular topic at the moment,” explained the institute’s leading researcher Jānis Rižikovs.

A similar process is carried out by Finnish scientists, who use spruce bark instead of birch bark, as with the Latvian example. The polyphenolic compound obtained from both can also be used to protect materials from moisture. The engineering doctor pointed out that after both processes, a solid residue remains. Although it was not originally planned to be used in the project, specialists from Latvia and Finland decided to experiment.

“Knowing that both of these compounds are very friendly with each other and a reaction could help each to harden, the idea was to mix them together and just press them together.

Knowing already our previous experience with the temperatures at which suberic acids react and harden, and our experience with what ratios could be put together, we experimented at different temperatures, with different material ratios, and created this slab, which turned out to have not only good mechanical resistance, but also with moisture resistance.”

It os hoped the new, sustainable building material could be used for facades. Due to the dinstinctive smell of the boards, it remains to be determined whether the material can be used indoors.

“We can use these suberic acids as a binder with any residues. We also have experience with mushroom cultivation substrate residues to transform them into a valuable biocomposite, with straw, hemp stalks and other biomass that remains. Anything can be compressed. (..) This was only the result of one project and one of the [results], maybe not even the most important, but as [astronaut Neil] Armstrong said, “One small step for a man, one giant leap for mankind.”

Entrepreneurs are interested in the new product. It is true that in order to produce the material in large quantities, a major production plant must be built in the country, said Rižikovs, estimating that if the joint cooperation succeeds, the building material could be found on store shelves, within five years.